BIOROCK® sewage treatment

The BIOROCK-10 is a compact, non-electrical sewage treatment unitThe Biorock is one of the sewage treatment systems we install. We also offer the Matrix and Mantair systems, as well as the Marsh ENsign and Mantair.

BIOROCK® was established in 1988 and is now an internationally acclaimed and experienced company leading in (compact) sewage water treatment technology. BIOROCK® has a total concept: our own R & D, manufacturing facilities and worldwide sales & technical support network.

The BIOROCK® product range can be used to clean sewage from a single house up-to public restaurants, hotels, schools, shopping malls, Safari Lodges and other facilities.

BIOROCK® has established a global dealer network, selling to thousands customers worldwide (> 75 countries). The unique-simple concept & support provided by BIOROCK® distributors have ensured that our brand & Global Team are well-respected and well-known throughout the globe.

The BIOROCK® Team

Our team of waste water experts are unrivalled in the waste water treatment industry. BIOROCK® is a company fuelled by a dedicated team with years of operational experience in waste water treatment. Their energy and a close working relationship with our global dealer network have enabled growth into new services- solutions- markets and innovative solutions.

The next generation of waste water technology, in line with worldwide environmental legislation – enabled by our clear vision in this ever-changing market – will be lead by the global leaders of compact sewage treatment – BIOROCK®.

Over the past 20 years, we have successfully completed a matrix of different solutions to our clients waste water treatment & recycling needs, this has placed us at the forefront of the waste water solutions market around the world.

Our Mission

Our mission is to provide a leading solution to domestic waste water problems. BIOROCK® has developed a global network of qualified technical partners to support our customers. With the BIOROCK® solution, purified water can be discharged into surface water or reused for irrigation. The key to our success is our collaborative approach to strategy development.

BIOROCK®-S Series

(Small STP – Sewage Treatment Plant)

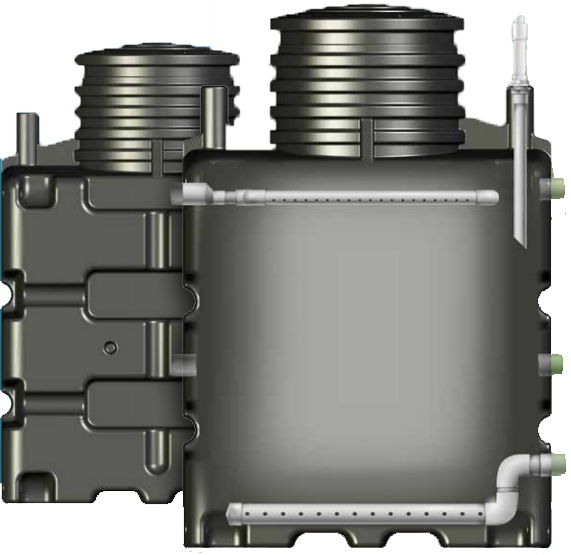

The BIOROCK®-S series units are packaged domestic waste water treatment plants, providing a consistent high quality effluent that meets the highest standards. The biological purification technique requires no electricity or moving parts. As a result of this; maintenance and operational costs are particularly low, and reliability maximized. The units are assembled in durable HDPE tanks with lightweight, low profile, access covers. The plants are supplied as a complete package for simple installation.

The BIOROCK®-S Series utilizes a unique fixed bio-film technology with specific functions to achieve an odor free effluent, suitable for irrigation or re-use in the grey water system. Due to the high quality of the treated effluent produced, should it be desired, it can be discharged into sensitive water courses.

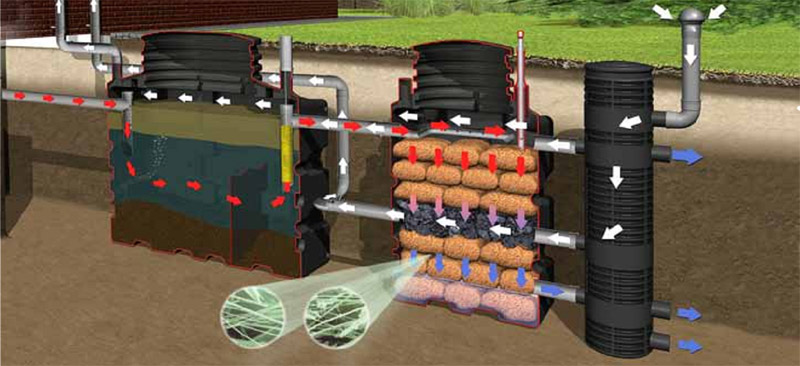

The BIOROCK®-S Series system functions as a two stage Sewage Treatment Plant. The raw sewage first enters a Primary tank to provide pre-separation and initial breakdown of organic solids. The sewage then passes through an effluent filter before discharging into the BIOROCK® unit itself which incorporates the aerobic filtration process. Where required the BIOROCK® S Series can be retrofitted to a traditional septic tank.

This later stage of the process is defined by layers of BIOROCK® media. The BIOROCK® media is pretreated with enzymes in order to achieve rapid start up and to stimulate the growth of the correct bacteria type; these bacteria colonize the media in vast numbers and rapidly digest the organic waste. The treatment philosophy has been developed around a combination of aerobic/anoxic biological degradation and filtration. The BIOROCK® technology advantage is further characterized by – minimal maintenance requirements & ability to handle intermittent (seasonal) loadings. (E.g. Holiday homes, Safari Lodges, Camping Sites, etc.)

The BIOROCK-10

The Biorock-10 is a compact, non-electrical sewage treatment unit.

100% Natural Process

The purification process is fully biological. The bacteria grow on and inside the special BIOROCK® Media. The BIOROCK® units use many of the same water purification processes and principles encountered in nature. Useful bacteria are responsible for degrading the pollutants. These microorganisms are already

present in the wastewater and are stimulated by presence of enzymes.

Pre-treatment

Primary settlement is always the first stage in the treatment process. The BIOROCK® unit (reactor) must be installed after a primary settlement tank. Coarse materials are retained, heavy particles sink to the bottom, while floating items remain at the surface.

Biological

The all-biological treatment process takes place within the BIOROCK® trickling filter. The aerobic bacteria, which proliferate within the media, require oxygen. Their metabolism removes the pollutants. A natural oxygen supply by means of the innovative draft system provides oxygen while reducing the operating costs.

The revolutionary and Fool-proof BIOROCK®-S units are available in various capacities. The BIOROCK®-S series is a range of Compact packaged treatment plants, denominated into 5, 10 & 15 person systems. The BIOROCK-10 units are designed for single or multiple homes.

Revolutionary technique!

- No electricity required

- No moving parts

- 24 Hour start-up period

- Long absence periods acceptable

Unique advantages

- Completely silent

- Lowest operational costs

- Superb effluent quality

- Septic tank conversion unit

Sustainability

- Solar power option

- Low carbon footprint

- Minimum annual maintenance

- Long desludge interval