Sewage Treatment

Biopure range: Sewage Treatment Plants Uni: 6 – 50The system we install is the Bio-Pure. We also offer the Solido, Mantair, WPL Diamond and Biorock® systems.

Bio-Pure: Simple Solution Sewage Systems

The Bio-Pure sewage treatment range is designed to serve both domestic and commercial properties that have no access to mains drainage. The units are independently tested and certificated to BS EN 12566-3 in order to clean the final effluent to a standard of 20mg/l Biological Oxygen Demand (BOD ) and 30mg/l Suspended Solids on a 95 percentile basis.

The range caters for between 1 and 40 persons.

The unit offers a very discreet solution to on-site sewage treatment as the small lid is flush with the ground and unlike its rivals, the compressor housing is under the lid, with no visually intrusive kiosk. The Bio-Pure itself is craftsman built, superb quality (using thicker fibreglass than its rivals), very robust and carries a 25yr guarantee on all GRP parts of the tank.

Why use the Bio- Pure System?

Affordable product with low running costs

25 years warranty on GRP and 2 year warranty on air pump

Can be adapted to meet individual needs

Visually unobtrusive lid with quiet air pump housed underneath

The tank is odourless as solids are treated

Typical 3-5 years emptying periods

No requirement for concrete means easy installation and low costs

No moving parts so that the unit will not fail

How does the Bio-Pure work?

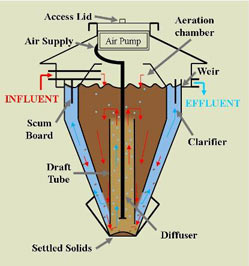

The Bio-Pure is a two-chamber unit and consists of a conical tank that contains an inner tank aeration chamber, which is open at the base. The space between the inner and outer tank is the clarifier chamber. A draft tube, positioned 100mm from the base of the clarifier, extends up into the aeration chamber.

Air from the compressor housed under the lid is piped to a diffuser in the draft tube. Raw sewage enters the aeration chamber and air surging up from the draft tube aerates the sewage, causing an aerobic bacterial colony to establish and digest the organic matter. As more raw sewage enters the chamber, an equal amount of effluent displaces through the open bottom into the clarifier. The quiet conditions in the clarifier allow all the suspended solids to sink to the base of the clarifier. They are drawn back up the draft tube by the upward flow of air, for further digestion in the aeration chamber.

The clear effluent rises to the top of the clarifier and passes over a weir into the outlet pipe. The Bio-Pure constantly recycles the sewage via gravity and achieves nearly total solids digestion. Most sewage treatment units consist of three chambers, the first one being a Primary Settlement Tank, where the solids form a septic sludge. They require regular emptying by tanker. Because the Bio-Pure digests the solids as well as the organic matter in the liquid, the unit has a much longer emptying interval than any three stage unit. The interval is 3 to 5 years.

Bio-Pure Range

The Bio-Pure sewage treatment plant is available in 9 sizes to cater for up to 40 persons. The Bio-Pure 1-5 are single units and the Bio-Pure 6-9 are twin units.

In order to work out which plant is suitable for your property you must abide by the British Water Code of Practice: Flows and Loads-2 Sizing Criteria, Treatment Capacity for Small Wastewater Treatment Systems (Package Plants) (BW COP: 1/05).

A domestic dwelling is fairly straightforward to work out. This is usually the number of bedrooms in the property plus two. For example, a three bedroom house becomes five (requiring a Bio-Pure 2). However, if the treatment plant is required for more than one property, then two must added to each dwelling. For example, a three bedroom house plus two = five, a two bedroom house plus two = four and a four bedroom house plus two = six, will become fifteen (5+4+6). This will require a Bio-Pure 5.

For a non- residential property, the size Bio-Pure required will depend on the purpose of the property. Please contact us and we will be able to work out the correct size Bio-Pure required for your needs (sizes 1 to 9).