The WPL Diamond Sewage Treatment Range

WPL Diamond – Environmental Wastewater Solutions

The WPL Diamond sewage treatment range is specifically designed for domestic properties situated away from wastewater mains drainage.

The Diamond is marked and type tested in accordance to BS EN12566-3, the new European standard covering wastewater treatment plants, making it fully compliant with UK Building Regulations.

Utilising a unique design, each purposely sized plant offers high quality, discreet wastewater treatment whilst ensuring value for money, low ongoing running costs and complete peace of mind.

Benefits

Outstanding value for money

Reliable operation with its simple design and no internal moving parts

Low running costof the small, quiet air blower

Continuous bacterial digestion gives the DMS range up to 3 year de-sludging intervals (the DMC range generally requires annual de-sludging)

No odours as the process does not require primary settlement

Excellent performancemeeting normal environment agency consent standards

Low visual impactwith small lid, flush with the ground

Easy installationas the unique design minimises labour and materials

Robust constructionreduces the need for concrete backfill where ground conditions permit

Compact designdoes not require large plant for excavation or handling

Reduced soakaway

Over 40,000 units installedworld wide

CEmarked

Irish Agrément certified

Optional External Pump Chamber (EPC)

If the location of the Diamond plant is on an incline, in a high water table area or a long distance away from the designated discharge point (ie: soakaway/water course/ditch) the final effluent may require pumping.

The Diamond DMS range can be specified with an EPC which can deliver up to 100 litres per minute of effluent at a head of 4m. The EPC can be simply retro-fitted and is easy to maintain.

External Pump Chamber consists of:

240v, 0.25kw submersible pump, integral float switch with stainless steel internals

High level alarm beacon

Junction box

32mm MDPE Pipe outlet

Invert extension kit for the EPC also available (optional extra)

Installation

Process Description

- Located in the centre of the aeration chamber is a 200mm diameter draft tube (3), which extends to 100mm from the bottom of the clarifier. Air is released at the bottom of the draft tube through a disc plate diffuser (4).

- As the diffused air rises in the draft tube it causes an upward flow of process fluid. This draws the settled solids (5) from the bottom of the clarifier up through the draft tube where they are discharged at the surface of the aeration chamber.

- The design of the draft tube ensures continuous and complete mixing of oxygen with the sewage. This oxygenation allows the various aerobic organisms that biologically degrade the wastewater contaminants to grow.

- Gravity causes the aerated solids to settle at the bottom of the tank where they are again drawn back up through the draft tube.

- As raw sewage enters the aeration chamber, it displaces biological solids from the aeration compartment to the clarifier. Less turbulent conditions in the clarifier allow the digested solids to settle to the base where they are returned back to the aeration compartment.

- The clarified (treated) effluent flows slowly up through the clarifier and over a weir (6), which extends around the periphery of the tank.

- The effluent collects in an outer trough where it is discharged through a 110mm pipe connection. The scum baffle (7) located inside the overflow weir prevents floating solids (8) from passing over the weir.

Process Performance

Blower Installation

Service & Maintenance

Continuous bacterial digestion gives the DMS range up to 3 year de-sludging intervals (the DMC range generally requires annual de-sludging).

Availability

Guarantee

WPL

WPL has over 16 years’ industry experience and services an extensive customer portfolio comprising the UK’s major water utilities, all areas of the commercial sector and the domestic market place.

The company’s consistent focus on ecology, coupled with extensive research & development into new technology, have enabled it to far exceed all existing and proposed discharge consent standards enforced by the Environment Agency, SEPA and other regulatory authorities.

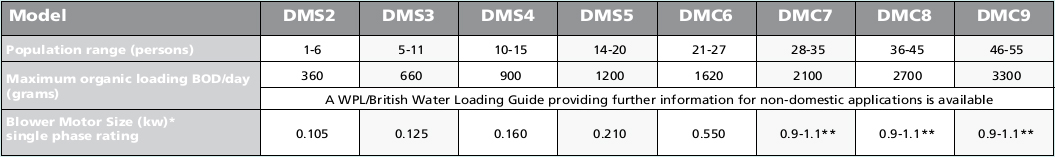

Loadings (based on British Water Code of Practice) and Blower Power Rating

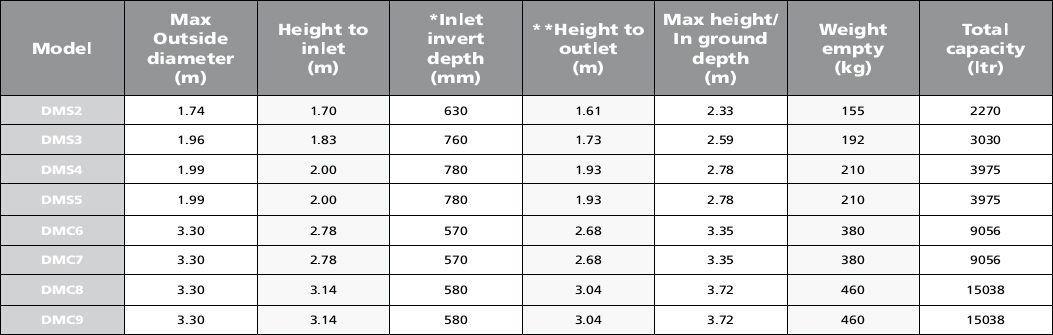

Technical Data and Dimensions